?So, what are nanofibers

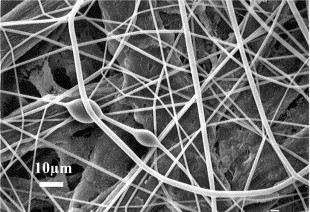

Nanotechnology includes the use of nanomaterials, mostly in medicine and also in engineering science. Nanofibers are an example of these nanomaterials which are mostly produce by electrospinning. Electrospinning is the use of strong electric field to produce nano sized continuous fibers from polymer solution. This polymer solution is drawn from a syringe, under the high electrostatic forces, to the size from 40 nm to 2000 nm in diameter (Teo and Ramakrishna, 2006). Polymer based nanofibers can be natural, synthetic, or a combination of both. Natural polymers have better biocompatibility and lower immunogenicity. On the other hand, synthetic polymers offer greater flexibility in their synthesis and modification (Hu et al., 2014) Synthetic polymers have been more frequently applied to make nanofibers than natural polymers. Polymer blends are commonly used to achieve favorable physical properties of nanofibers.

Wafa K.Essa et al.,2021

Applications of nanofibers

Drug delivery

One of the nanofiber’s potential application areas is drug delivery. In addition to the advantages of high surface area and porosity, as well as small fiber size, nanofibers are excellent materials for drug delivery due to the flexibility and diversity in the fiber production process. The parameters, including polymers, solvents, the solubility of drugs, electrospinning equipment, and drug loading methods, in the production process are crucial variables for drug delivery material designing (Okutan et al.,2014).

Water filtration

Water filtration is a necessary and important technology because of the increasing water pollution and population growth. Filtration membranes are selective separation materials for segregation, purification, and concentration. Membranes can be used to remove viruses, colloids, materials, heavy metal, etc. Filtration membranes can be classified by raw materials: glass fiber, synthetic fiber, and natural fiber. They can be sorted by products, for example nonwoven, woven fabric, knitted fabric, braid fabric, and nanofiber webs. Nanofiber webs belong to new filtration membranes compared with all other listed filtration membranes. Nanofiber webs show advantages in high surface area, high porosity, relatively small pore size, and high flux rate (Lihua Lou et al., 2020).

Biomedical application

Biomedical application means materials are utilized for the medical or biological related areas for monitor, detection, or treatment. Nanofiber webs have been applied to biomedical application areas due to the high surface area. There are mainly three directions for nanofiber application in biomedical areas: scaffolds in tissue engineering,61 drug delivery and drug delivery mechanisms, and enzyme immobilization. Drug delivery and drug delivery mechanisms have been discussed, so we will analyze the two other applications (Lihua Lou et al., 2020).

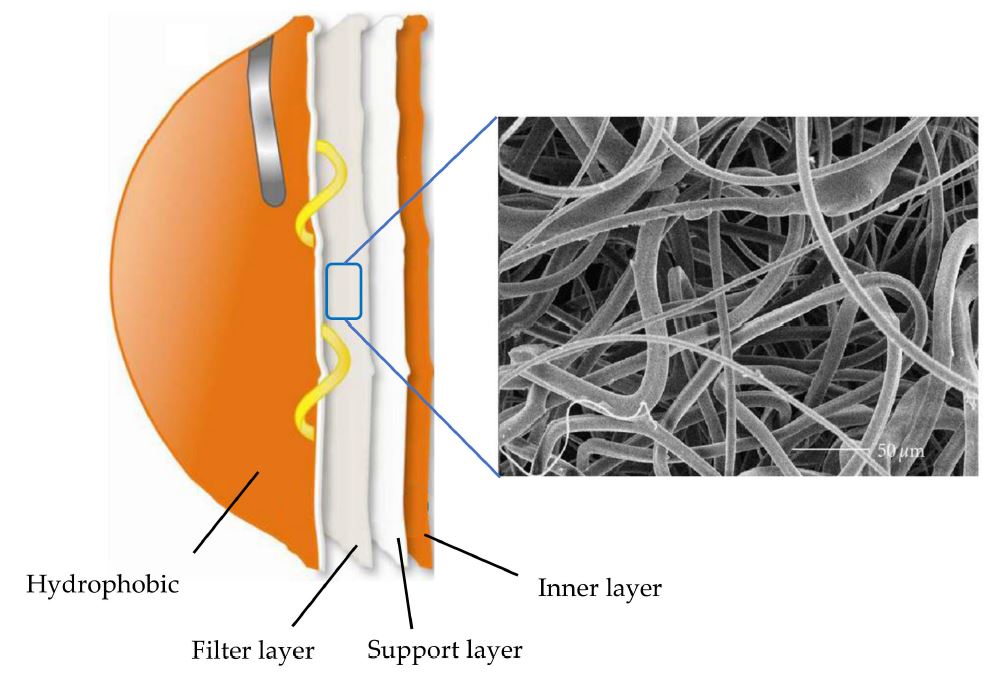

Protective clothing

Protective clothing is worn to protect the wearers’ body or other aspects of chemical, physical, and biological hazards. This clothing can be found in use in hospitals, battlefields, chemical-related industries, and the food industry. Recently, high surface area nanofiber-based materials have been applied to protective clothing. Compared to traditional protective clothing, nanofiber protective clothing exhibits high elasticity, comfortability, breathability, isolation efficiency, and lightweight characteristics (Lihua Lou et al., 2020).

Air and gas filtration

Air pollution, which has become increasingly serious all over the world especially in developing countries, can cause high blood pressure, cardiovascular disease, respiratory diseases, skin irritation, asthma, birth defects, cancer, and nausea, due to the adhesive chemical and biological components in particle material. Therefore, high efficiency air filters with PM removal efficiency higher than 99.97% and 99.999% are necessary requirements for air filtration products. Compared to traditional woven, nonwoven, and knitted fabrics, nanofiber webs with small diameter, high surface area, small pore size, and high porosity, and high filtration efficiency are excellent filter materials for the removal or isolation of small size particulates.

Nanofibers in masks

Face masks play an important role in air filtration especially in the corona pandemic. As already explained, nanofibers can be very useful in air filters, this includes face masks as well. Four mechanics of PM filtration include: interception, inertial impaction, diffusion and electrostatic attraction. While the first 3 are mechanical mechanisms and will filter large and very small particles, the last one is electrostatic mechanism and will be provided by nanofibers. Electrospun nanofiber-based filter media possess a high ratio of surface/volume, low-pressure drop, good interconnectivity of voids, and controllable connectivity and morphology, rendering them desirable to achieve excellent filtering.

There are several parameters, including fiber diameter, pore size, specific surface area, thickness, and nanofiber structure, that will or could affect the air/gas filtration efficiency. On the basis of the existing research, small nanofiber webs with a diameter lower than 300 nm can reach 99% filtration efficiency. However, nanofibers with too small a diameter can increase the pressure drop. Pore size has a direct and similar relationship as the diameter for filtration properties. The uniformity of pore size also plays an important role in the filtration performance of nanofiber webs. Unlike fiber diameter and pore size, the high surface area can effectively promote filtration efficiency. It is also the reason that nanofiber has become popular in air/gas filtration. The thickness of nanofiber webs is proportional to the pressure drop, and the structures of nanofiber and nanofiber webs are affected by the incorporated particles and polymers in the nanofibers.

Wafa K Essa et al.,2021

Nanofibers are undoubtedly a very useful technology in air filtration and respirators, and have a very bright future in many other engineering applications. By now there are a few well-known brands (such as Respilon, Azonano, Nanosilver and others) in the respirators business that are providing nanofiber technology in face masks and working on improving its properties. Here in Nanoxin, we are producing nano fiber-based face masks using the latest technology (designed and manufactured by our R&D team and engineers) based on the latest studies and publications.

Refrences

Teo, W. E., and Ramakrishna, S. (2006). A review on electrospinning design and nanofibre assemblies. Nanotechnology 17, R89–R106. doi: 10.1088/0957-4484/17/14/R01

Hu, X., Liu, S., Zhou, G., Huang, Y., Xie, Z., and Jing, X. (2014). Electrospinning of polymeric nanofibers for drug delivery applications. J. Control Release 185, 12–21. doi: 10.1016/j.jconrel.2014.04.018

Okutan, N.; Terzi, P.; Altay, F. Affecting parameters on electrospinning process and characterization of electrospun gelatin nanofibers. Food Hydrocolloids 2014, 39, 19−26.

Lihua Lou, Odia Osemwegie, and Seshadri S. Ramkumar (2020). Functional Nanofibers and Their Applications. Industrial and engineering chemistry research https://dx.doi.org/10.1021/acs.iecr.9b07066